With the continuous improvement of mechanization and automation in molding,

the demand for molding sand has significantly increased, resulting in a greatly shortened

cycle time for old sand. Many foundriesInsufficient sand cooling equipment was not installed in the sand treatment system for

the molding sand molding line, resulting in reuse during hot summer and full load operation

The problem of "hot sand" caused by excessive temperature of old sand. Excessive temperature

of molding sand can cause a series of difficulties in production, such as unstable performance of molding sand and easy adhesion to templates and sand buckets

The sand treatment equipment can easily dehydrate the surface of the mold, leading to an

increase in casting scrap rate and deterioration of labor conditions. The main reason for the high

temperature of the molding sand is

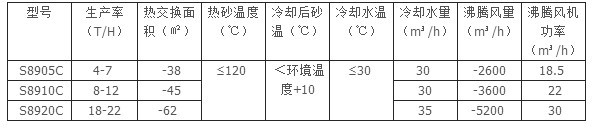

The temperature of recycling old sand is too high. The boiling cooling bed is designed to improve

the temperature of old sand

The cooling methods for old sand used to be mostly using cooling drums, increasing the length of the

old sand conveyor belt, and expanding the intermediate sand storage hopper. These methods apply to

The effect is not ideal. The boiling cooling bed has improved the method of mainly relying on

air convection and natural cooling in the past, by using strong cold air to keep the sand in a stable state

In a boiling state, it is in full contact with the heat exchanger installed above the boiling plate,

allowing the sand flow to undergo secondary heat exchange. It controls the pressure of the air flow discharged from the equipment

Force, which creates negative pressure, can effectively advance the sand flow while also absorbing

fine dust from the sand flow